Hard Imaging eclipses all other decorative processes

This process eclipses other decoration processes as it produces a permanent image embedded within the anodized coating Mil Spec Type II (Anodize) and Type III (Hardcoat). That means the anodizing process can be applied to a multitude of shapes without adding undesirable surface thickness.

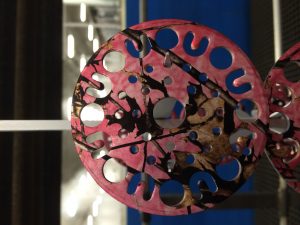

The ladybug image above is a photograph of Hard Imaging on a sheet of aluminum.

Any image or decorative design that can be digitally created or controlled on a computer can be permanently embedded in an anodized surface. Because of the digitally controlled computer interface of the image, final designs or images have the tremendous advantage of being able to adjust the image size to fit the product.

Current technologies such as “film dipping” do not allow the decorator or facility to adjust the image to the part. This locks the facility into buying one size of a repeating pattern of film that can’t be changed or modified to add text. For example, a film dip image with a 5” x 4” leaf doesn’t fit well on a 1” x 2” part. The leaf ends up covering the entire part rather than allowing the full pattern to be reduced and blended into the surface of the part.

Hard Imaging™ surpasses all other current technologies with unbeatable durability, hi-resolution imaging, ability for variable data and design flexibility.

Today, the industry is used to seeing solid anodized colors (solid blue, red, black, etc.). This process allows a rainbow of colorful digital images to be embedded into the anodized coating while still meeting Type II and Type III anodizing specs.

Precision Parts, Designs and Instruments

Because of the embedded nature of the image, there is practically no surface thickness and little or no weight added. This means threading two parts that have been image anodized will thread with ease because the threads have not been affected. Equipment with high tolerance fittings can be imaged without retooling.

Weight and Décor Applications

When it comes to reducing the weight of an aluminum part, this process is indispensable. Typical coatings and paints add weight to a product. With this patented process, decorative designs are no longer burdened with transporting extra weight – think aircraft, vehicles, boats, etc.

Day-to-Day Products and Benefits

- Ever thought of aluminum windows, doors and siding anodized with a natural grained wood pattern? The market is only limited by our imagination – cookware, decorations, jewelry, file cabinets, back splash boards, refrigerators, etc.

- Sporting goods from archery and fishing equipment to rifles and bats

- Military applications abound when you think of the camouflage requirements of our armed services

- High quality designs and imaging in full color

- Lightweight and durable

- Weather resistance provides excellent cost savings